Woven Filter Mesh For Fine Filtration, Liquid-Solid Separation And Screening &Sieving

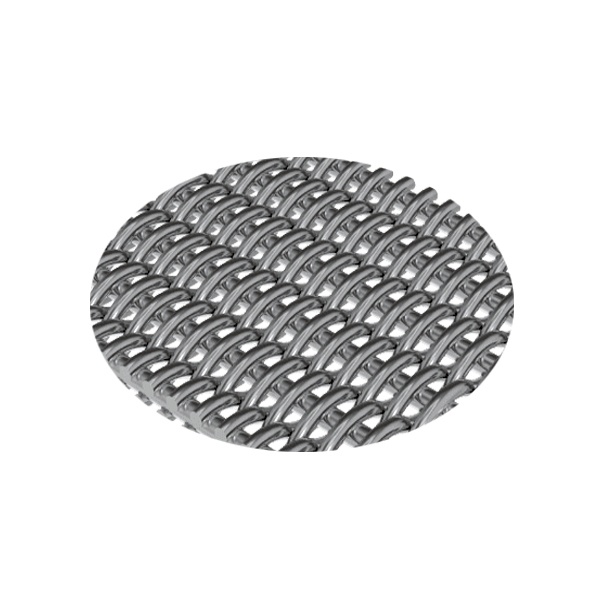

Plain Dutch Weave

This simple dutch weave is the most common filter cloth. Generally, the diameter of warp wire is larger than the weft wire. Warp and weft wires are interwoven closely together at set intervals. It is ideally suited for filtration applications, as well as the separation of slurry and liquid materials.

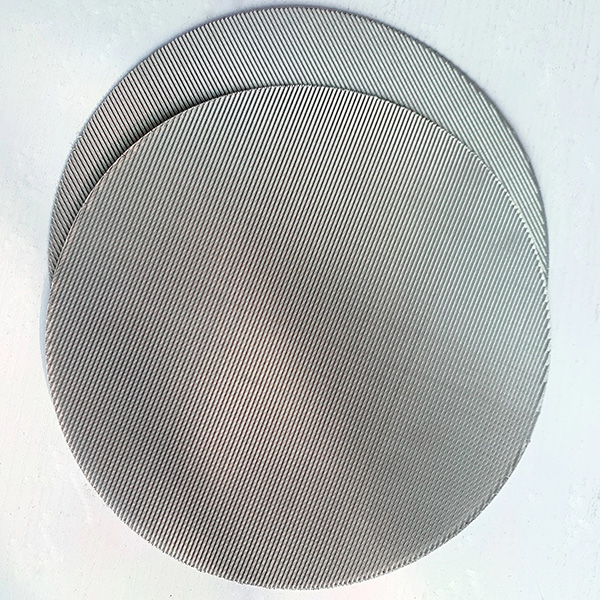

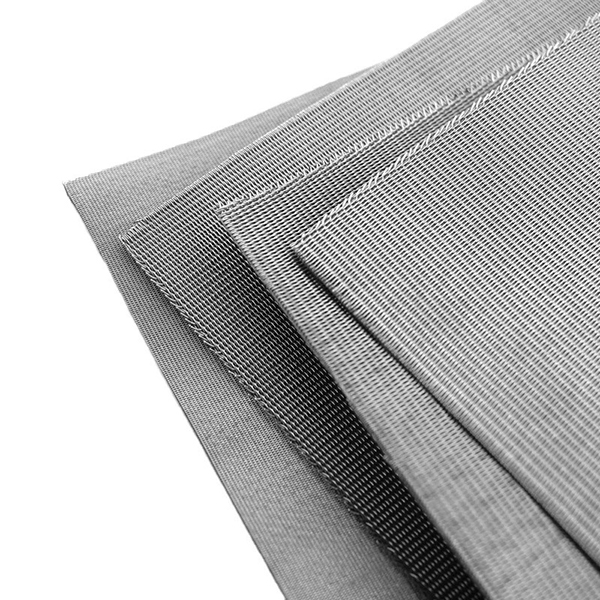

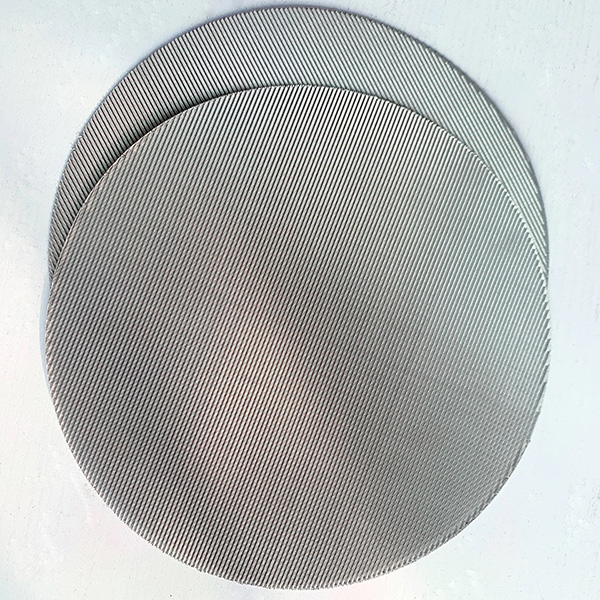

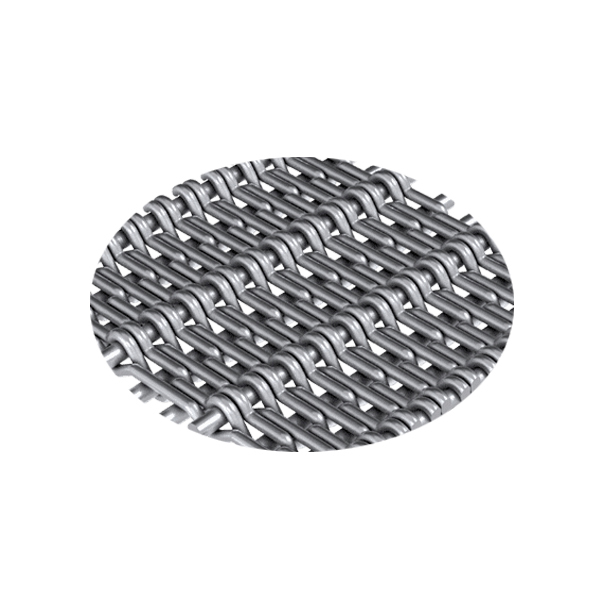

Twill Dutch Weave

This weave type offers a significant upgrade in strength over plain dutch weave wire cloth. It actually combines the Dutch and twill weaving process to produce an extremely fine mesh filtering cloth that is created by passing weft wires over and under two warp wires. As a result, it is suitable for various liquid and gas filtration applications.

Reverse Dutch Weave

This weave type is in a reverse of the plain dutch weave wire arrangement. The diameter of warp wire is smaller than the weft wire. Warp and weft wires are interwoven closely together at set intervals. It is well-suited for high pressure vertical and horizontal filter leaf applications where backwashing and filter cake removal are important.

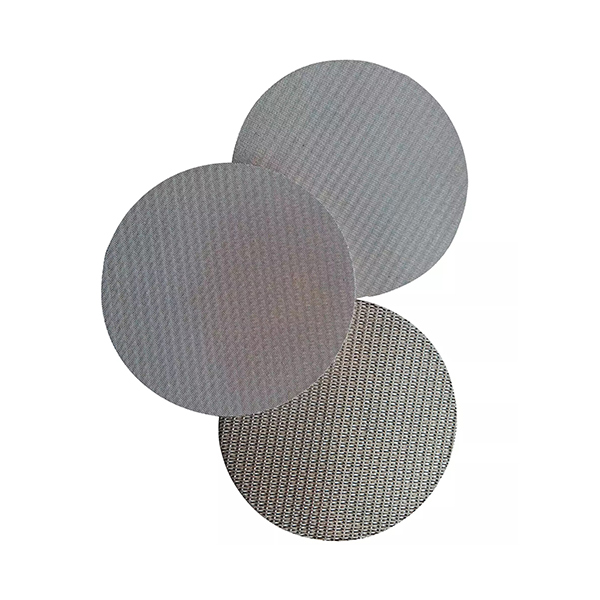

3- Heddle Twill Dutch Weave

Similar like 3-heddle weave, this type of weave has a larger diameter of warp wire than the weft wire. Besides, weft wires are closely arranged, leaving no gaps between weft wires. As a result, it is suitable for filtration applications that require high filtration accuracy and heavy load bearing capacity.

Specification

Material: stainless steel, SS304,SS316,SS316L, SS201,SS321,SS904,etc.brass, copper, nickel,iron,galvanized.

Filter rating: 2–400 μm

| Mesh No. | Wire Diameter mm | Mass kg/m2 | Filter Rating μm |

| 6 × 45 | 0.10 × 0.60 | 5.3 | 400 |

| 12 × 64 | 0.60 × 0.40 | 4.2 | 200 |

| 14 × 88 | 0.50 × 0.35 | 2.1 | 150 |

| 12 × 90 | 0.45 × 0.30 | 2.6 | 135 |

| 13 × 100 | 0.45 × 0.28 | 2.58 | 125 |

| 14 × 100 | 0.40 × 0.28 | 2.5 | 120 |

| 16 × 125 | 0.35 × 0.22 | 2 | 110 |

| 22 × 150 | 0.30 × 0.18 | 2 | 100 |

| 24 × 110 | 0.35 × 0.25 | 2.65 | 80 |

| 25 × 170 | 0.25 × 0.16 | 1.45 | 70 |

| 30 × 150 | 0.23 × 0.18 | 1.6 | 65 |

| 40 × 200 | 0.18 × 0.12 | 1.3 | 55 |

| 50 × 230 | 0.18 × 0.12 | 1.23 | 50 |

| 80 × 400 | 0.12 × 0.07 | 0.7 | 35 |

| 50 × 250 | 0.14 × 0.11 | 0.9 | 40 |

| 20 × 250 | 0.25 × 0.20 | 2.8 | 100 |

| 30 × 330 | 0.25 × 0.16 | 2.55 | 80 |

| 50 × 400 | 0.20 × 0.14 | 2.14 | 70 |

| 50 × 600 | 0.14 × 0.080 | 1.3 | 45 |

| 80 × 700 | 0.11 × 0.076 | 1.21 | 25 |

| 165 × 800 | 0.07 × 0.050 | 0.7 | 15 |

| 165 × 1400 | 0.07 × 0.040 | 0.76 | 10 |

| 200 × 1400 | 0.07 × 0.040 | 0.8 | 5 |

| 325 × 2300 | 0.035 × 0.025 | 0.48 | 2 |

| 400 × 125 | 0.065 × 0.10 | 0.7 | 50 |

| 260 × 40 | 0.15 × 0.25 | 2.15 | 65 |

| 130 × 35 | 0.20 × 0.40 | 3.1 | 90 |

| 152 × 24 | 0.30 × 0.40 | 3.6 | 190 |

| 132 × 17 | 0.30 × 0.45 | 4.1 | 240 |

| 72 × 15 | 0.45 × 0.45 | 4.5 | 350 |

Product Display